| Authors: | Seyyed Amin Rounaghi, Danny E.P. Vanpoucke, Hossein Eshghi, Sergio Scudino, Elaheh Esmaeili, Steffen Oswald and Jürgen Eckert |

| Journal: | J. Alloys Compd. 729, 240-248 (2017) |

| doi: | 10.1016/j.jallcom.2017.09.168 |

| IF(2017): | 3.779 |

| export: | bibtex |

| pdf: | <J.Alloys Compd.> |

|

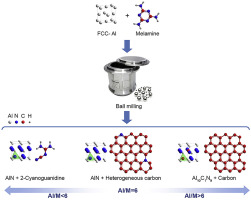

| Graphical Abstract: Evolution of the end products as function of Al and N content during ball-milling synthesis of AlN. |

Abstract

A versatile ball milling process was employed for the synthesis of hexagonal aluminum nitride (h-AlN) through the reaction of metallic aluminum with melamine. A combined experimental and theoretical study was carried out to evaluate the synthesized products. Milling intermediates and products were fully characterized via various techniques including XRD, FTIR, XPS, Raman and TEM. Moreover, a Boltzmann distribution model was proposed to investigate the effect of milling energy and reactant ratios on the thermodynamic stability and the proportion of different milling products. According to the results, the reaction mechanism and milling products were significantly influenced by the reactant ratio. The optimized condition for AlN synthesis was found to be at Al/M molar ratio of 6, where the final products were consisted of nanostructured AlN with average crystallite size of 11 nm and non-crystalline heterogeneous carbon.