Today I had to get to work myself, unlike the first day of the ICACC where I was only a spectator. At 8h30 I kicked of the GYIF as the first speaker in a session called “Theoretical Modeling and Applications” with my presentation: Computational Materials Science: Where Theory meets Experiment. Intended for a general audience of (expectedly mainly) experimental materials scientist this presentation was aimed to show the audience that computational materials science has in the last decades developed to the level where results relevant for real-life applications in materials science can be obtained. For this I used three examples of my own work: (1) Pt nanowires on Ge(001), where I used simulated STM to build an accurate atomistic model of these wires, (2) doped cerium oxides, where the influence of doping on lattice parameter and thermal expansion coefficients was studied for the purpose of matching them to those of other materials, and (3) Metal-Organic Frameworks, where I showed that the spin-configuration of the MIL-47(V) MOF is linked to the transition pressure inducing breathing.

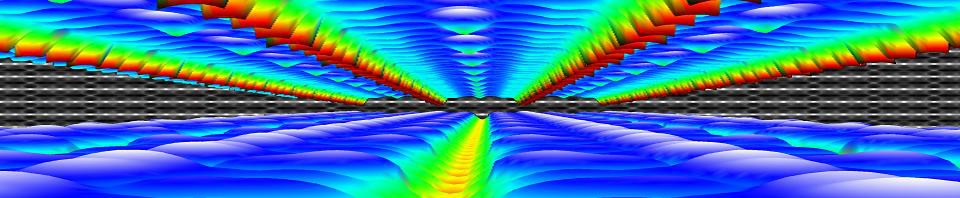

Later on during the morning, I had the pleasure of chairing the session “Additive Manufacturing” together with Valerie Wiesner from NASA. During this session Mahref Vali and Lisa Rueschoff presented their most recent work on 3D printing of ceramic materials, a technique which will allow the printing of ceramic components in the future. The third speaker of this session, Rumi Kitazawa, delighted us with an inspiring talk on the “Engineering applications of Menger sponges”. A Menger sponge is a fractal related to the Cantor set, as such a fully developed Menger sponge can not be build with any real material, however, using 3D printing it is possible to build a structure with Menger sponge like features (i.e. with holes down to a certain size). By comparing experimental stress tests on such 3D-printed systems with calculations of the strain energy in such a structure, Rumi was able to show these Menger materials have a peculiar, albeit very organised, strain pattern along the main diagonal of the material. The combination of large and small pores present in these Menger sponge materials may make this behavior relevant for MOF (and other porous) materials, where the large pores reflect inter-grain pores, while the small pores are the pores of the MOF. So this is definitely a topic to remember.

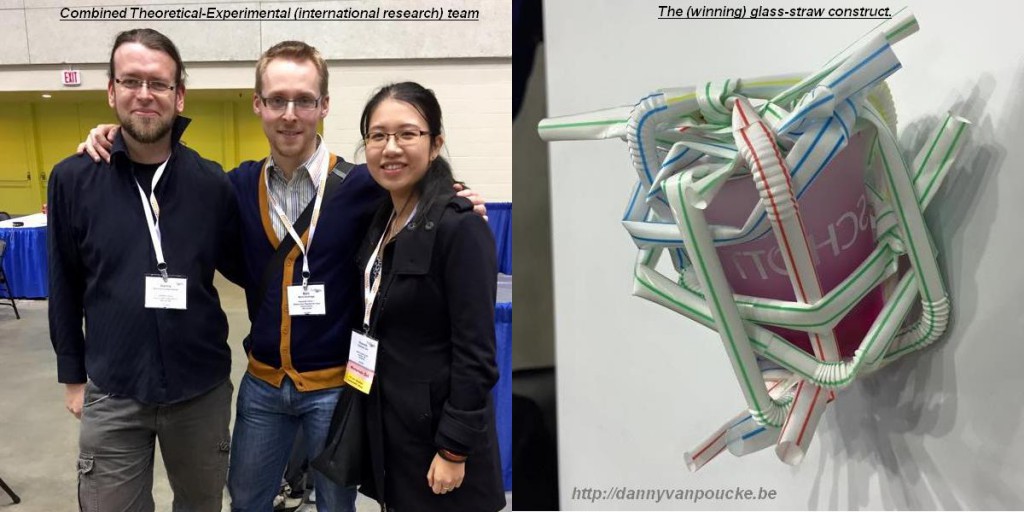

Next to presentations, conferences also contain social events. Today, there were two social events; at noon there was a luncheon by the GYIF where the young investigators could mix with people from industry and senior group leaders. In the evening there was the first poster session and booth-stand where companies try to sell their services and lab equipment. Somehow, as a theoretician, I am always a bit at a loss at such events. To draw in more people, there was also a shot-glass contest. No, it was not the goal to drink as much as possible, but to build a protective structure around a shot-glass using only 15 drinking straws (no tape, wire, paper, staples,… allowed). To find the most protective structure, the shot-glass and straw constructions were dropped from various heights. Twenty four teams started at a drop height of 3 feet (~1 m), where already the first shot-glass didn’t survive the drop. Every round, the drop height was increased by 3 feet. For a drop of 20 feet (~6 m) there were only two teams remaining, including our team. Altough our glass survived its first bounce, the second bounce unfortunately broke our glass (darn). Then it was the turn of our remaining competitor, who’s shot-glass exploded into shards on first impact. Officially the result was a draw, although it is clear our construct had clearly the upper hand 😎 .